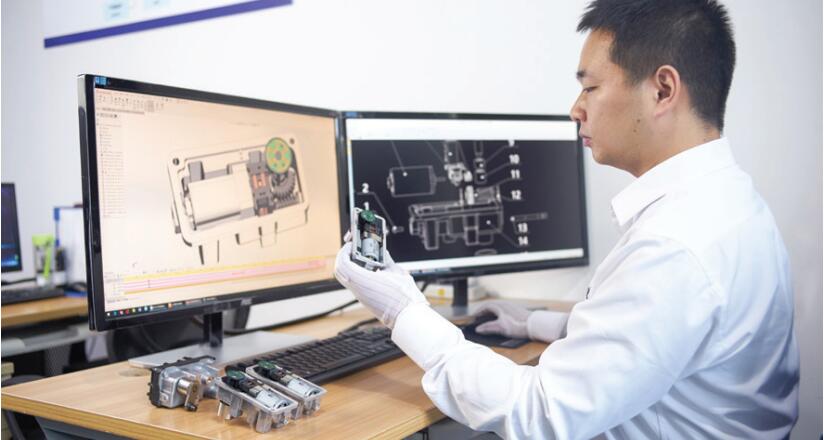

- Design department is responsible for 3D/2D

design of the e-Actuators and components - Collaboration with PE and CAE to ensure

technical optimisation proposal can achieve

the certain target - Modular Design / Customized interface

- Standardised PCBA design configuration

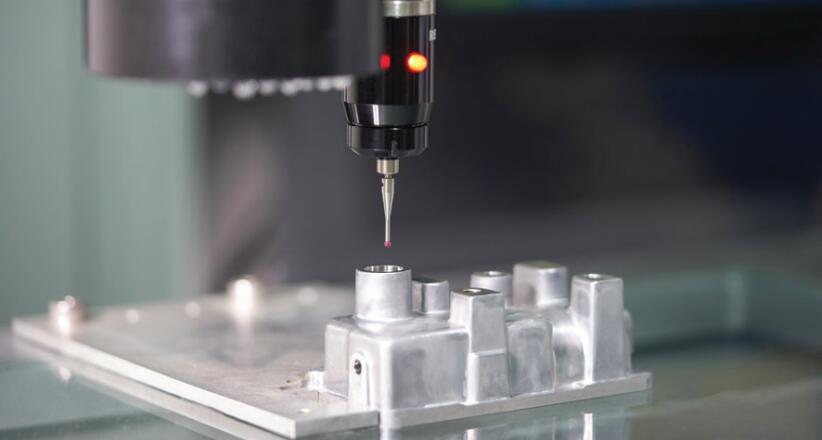

- FEA – Finite Element Analysis

- Housing TMF

- Parts heat distribution & transforming

- Support vibration fatigue

- Machine model & harmonic response

- 360° analysis of all risks. Provide durable

engineering validation testing methods to

guarantee performance and lifetime

SACER DESIGN AND VALIDATION CAPACITY

| ITEM | TESTING NAME | TARGET |

|---|---|---|

| 1 | HALT testing | Thermal cycle (high temperature & low temperature cycle) |

| 2 | Vibration testing | Sine sweeping frequency |

| 3 | Corrosion testing | 300hrs salt spraying testing |

| 4 | RT durability testing | 2000hrs (3 million duty cycle) RT full load durability testing |

| 5 | High/low temperature ageing testing | 400hrs +135˚C heat (-40˚C) testing within OVEN room |

| 6 | Water proof testing | IEC60529-IP65 water directly crash testing |

| 7 | Drop testing | 2m height drop |

| 8 | EMC | Radiated emission / conducted emission / Harmonic / flicker |

| 9 | ROHS & REACH testing | CCC/EC certification |

| 10 | Individual Parts DV testing | According to drawing |

| 11 | Vehicle durability | SA1130 more than 100K kilometers real vehicle testing score, SA1150 more than 6 month real vehicle testing |

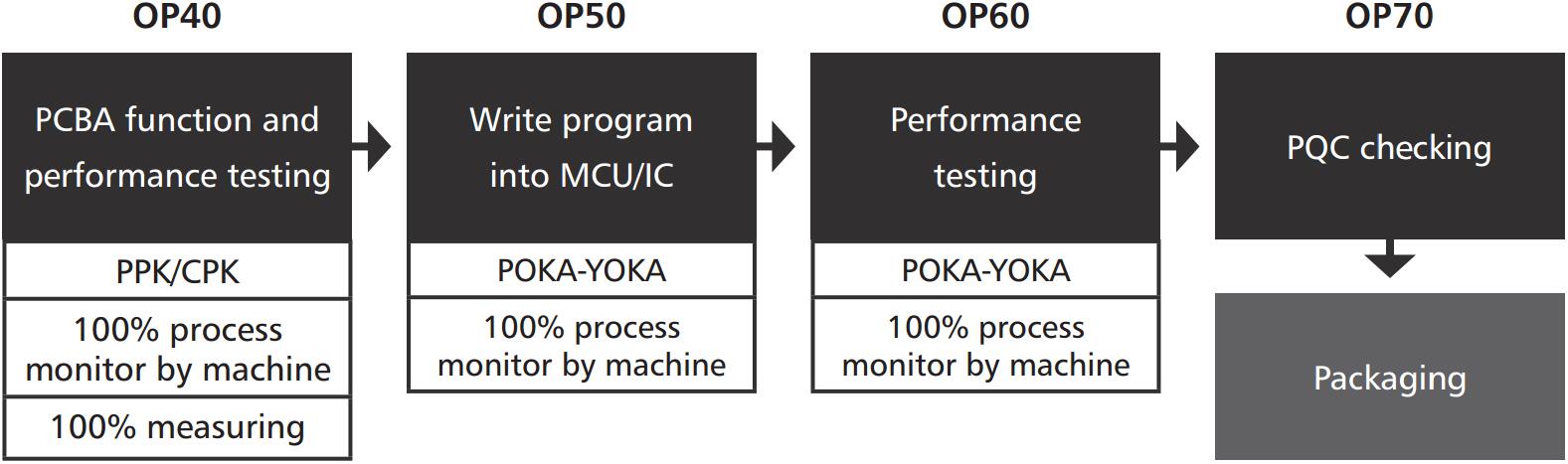

TEST AFTER FINISHING HOUSING ASSEMBLY